I now have a working Fisher Delta additive manufacturing device, or

"3d printer" if you prefer.

I bought the

beta version:

it's feature-complete, but still subject to change (in particular the

assembly instructions haven't been finalised).

Assembly took me about ten hours of part-time work; I suspect someone

better at this sort of thing could do it faster, and indeed I'd do it

faster if I were doing it again. I'm very glad I got it as a kit:

having put it together myself, I know just what goes where, and how to

get it apart if I need to. Do read the

list of required tools

before building; the 2.5mm drill is a bit obscure and I had to fake my

way round it.

I won't include the full set of assembly photos (which I took mostly

for my own reference in case things went Horribly Wrong), but I'll hit

some highlights.

The box is packed full of bags of hardware: many nuts and bolts and

such like, cables and electronics, laser-cut acrylic pieces, and

oddly-shaped 3D-printed components (green, in this case).

The general approach is to use standard metal parts, and mount them

into the 3D-printed plastic bits which can easily have nut-shaped

inserts built into them.

Three motors move clamps up and down the vertical rails; this

positions the effector head in three dimensions within the triangle.

The effector head itself is one of the most fiddly bits, perhaps

because it includes acrylic and 3D-printed parts as well as screws and

laser-cut wood.

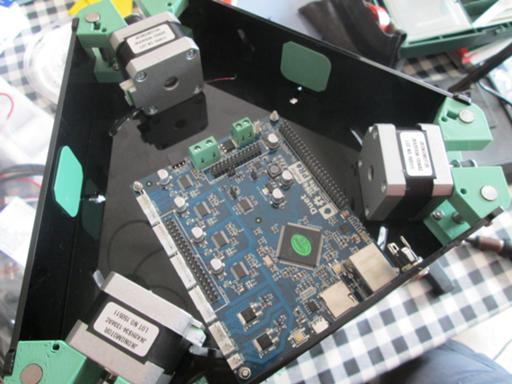

The whole thing is controlled by the RepRapPro "Duet" board, a 32-bit

ARM Cortex microcontroller (basically an Arduino). It presents an

AJAXy web interface over ethernet, which allows direct control (heater

temperatures, zeroing the axes, etc.) and accepts GCode files for

printing (slicing still has to be done beforehand).

It is… ALIVE!

Some higher-resolution pictures of my first test prints (in PLA). The

robot is supplied as GCode with the printer's firmware as a

recommended test; the snail is from

Thingiverse, and I scaled it

down to 15% before slicing and printing. (Note that, like any tool,

the Fisher doesn't do everything: these have had some cleanup already,

largely gentle filing, and would get more if I were planning to do

more with them.) Not perfect, certainly, but getting there.

Plans: miniatures for naval and other wargaming, replacements for

broken cooker knobs and similar bits of plastic that cost twenty quid

plus postage if you order them from the manufacturer, storage for

X-Wing miniatures, card stands for Firefly, a camera bag insert that

holds lenses in place, etc.

And yes, I'll run stuff off for mates in return for the

materials/power cost.

Comments on this post are now closed. If you have particular grounds for adding a late comment, comment on a more recent post quoting the URL of this one.