I've been trying out a new material in my 3D printer.

PETG is pretty much the same sort of thing as the PET

(polyethylene terephthalate) (polyester, Dacron, Terylene) used in all

sorts of textile and packaging applications. The "G" is for

"glycol-modified": cyclohexanedimethanol, which is already one of the

precursors in the synthesis of PET, replaces the ethylene glycol in

some of the polymer chains. Since that's a larger molecule, it stops

the chains packing together as easily, so it lowers the melting

temperature to something more readily achievable in the printer (mine

has a top end of 260°C).

There is the question of just what temperature to use. The packaging

of the Real Filaments spool I bought on spec suggests pretty much the

same as PLA (210°C printing temperature) or a little warmer, but

others disagree. (Others also say that it can stick so firmly to the

print bed that it can destroy a glass surface. Well, no problems so

far.)

I made three copies of a thing for which I had the file handy: a

stackable game-bits funnel

tray, designed to hold

game components in play and provide a chute for tipping them back into

their containers afterwards.

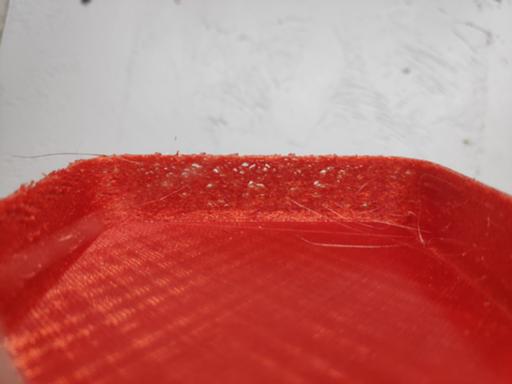

This is at 235°C: it's come out quite rough.

There are significant holes in the wall elements, suggesting that the

filament is sticking during the printing process.

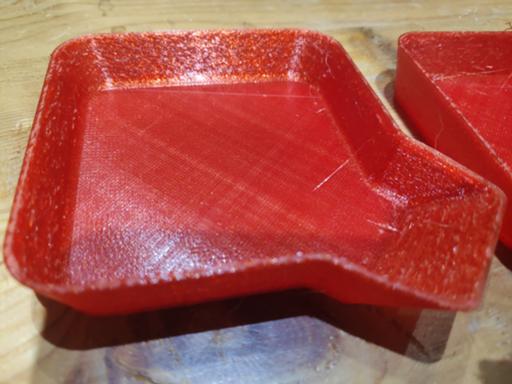

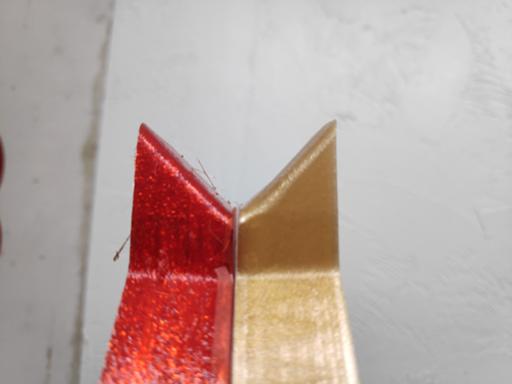

245°C: this looks pretty decent. All of these tests came out quite

"hairy", with thin stringing across the inside and outside. That's

usually a sign of excessive temperature, but given what happened to

the 235 piece I don't think that's what's going on in this case. (It

can be cleared up with a sharp knife, of course, though that's more

post-processing than I like to do.)

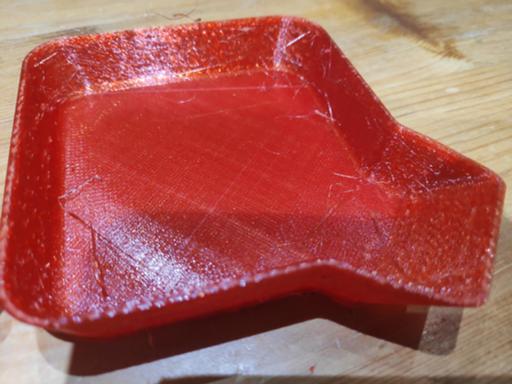

255°C: similarly "hairy".

There's not much to choose between 245 and 255, so I'll probably print

more at 250.

I'd been hoping for more shininess from this translucent filament

(well, it's translucent when it goes in to the printer). There's

some coloured internal reflection, but not a huge amount.

On the other hand the overall shape-holding is great - the 45°

overhang of the chute itself is dead straight, rather than the slight

slump of the same thing in PLA.

This filament costs about the same as PLA. PLA can be biodegraded but

only at high temperatures, and it looks as though some PET recycling

processes can handle PETG but others can't.

Comments on this post are now closed. If you have particular grounds for adding a late comment, comment on a more recent post quoting the URL of this one.