Last Saturday I went with some friends to tour the

Camden Town Brewery. (Images

follow; all are cc-by-sa.)

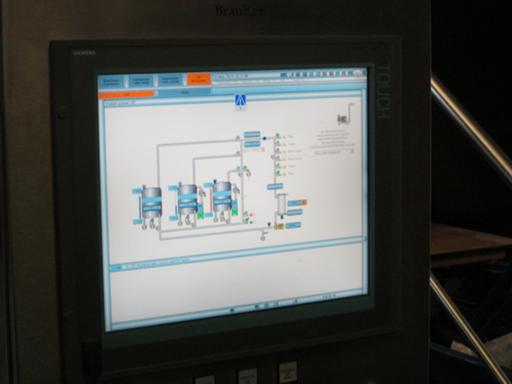

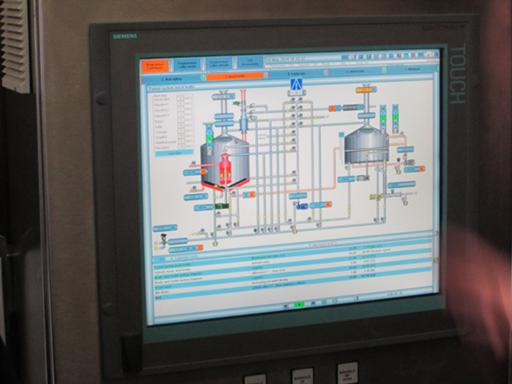

The control panel, mounted on the mash tun. This is the first brewery

tour I've been on where they had significant computerisation (as

opposed to 1970s-style process control electronics). The place was

only founded in 2010, which probably helps. Each valve and pump is

controllable from the touch-screen.

Some hop pellets. They mostly use Cascade hops, apparently because

they had trouble getting reliable supplies of normal British hops.

The top of the mash tun, with a sight-glass. There were quite a few

sighting points around the plant, again unusual in my experience but

it makes sense to me.

Grain is milled on site, generally within a few hours of brewing, to

minimise oxidation.

The lauter tun, and our guide. Valve solenoids are clearly visible.

This was some of the oldest-looking pipework in the place.

The fermenting vessels. This section is pretty cramped; these are

6,000l vessels, and there are 12,000l tanks outside. They can only

boil up 2,000l of wort at a time, so filling one of the big tanks can

take a day's worth of brewing the same thing.

They're planning to build a second and larger brewery, still within

Camden, which will probably take the lager work, while this one will

be for ales.

The base of the fermenters; since they often use bottom-fermenting

yeast, this shape helps the yeast collect together and stir itself up

with its carbon dioxide output.

A filter press; these are filled with diatomaceous earth and used

for lager-style beers.

The new centrifuge, which is being used to clear some brews without

the need for filtering.

Two of the many beer hoses that were lying about the place. Note the

10 bar maximum pressure. Apparently being sprayed with beer isn't as

bad as being sprayed with yeast.

The hopback, used for particularly hoppy beers (something of a house

style).

The bottling plant. Most of their output is keg, but they also bottle

and even can.

These one-shot kegs are used for long-distance beer sales (e.g. to

Japan). They cost about £1 each as opposed to the £60-odd of a normal

keg, even though the latter can be used around 300 times.

The canning plant. Note strip of can-lids left of centre.

In the brewery tap (open Thursdays to Sundays).

Comments on this post are now closed. If you have particular grounds for adding a late comment, comment on a more recent post quoting the URL of this one.