Just off Southwark Street in London is an unexpected piece of

industrial history. Images follow:

cc-by-sa on

everything.

New skyscrapers from Blackfriars Bridge, pleasingly cut off by

the mist.

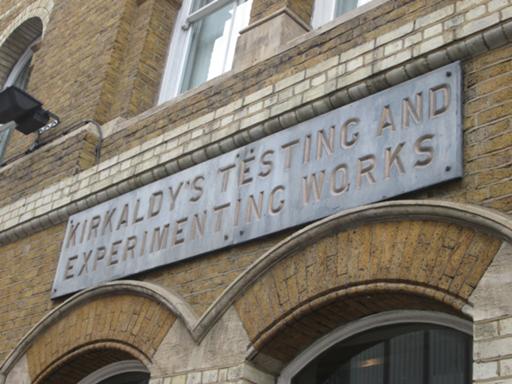

Original sign. David Kirkaldy moved the works to this site in 1874.

The Great Machine. This is basically a hydraulic piston that pulls (or

pushes, or bends) against a weighted arm, with a sample in the middle.

When originally built it could exert a million pounds of force, though

these days they only run it at a few thousands. The cylinder end:

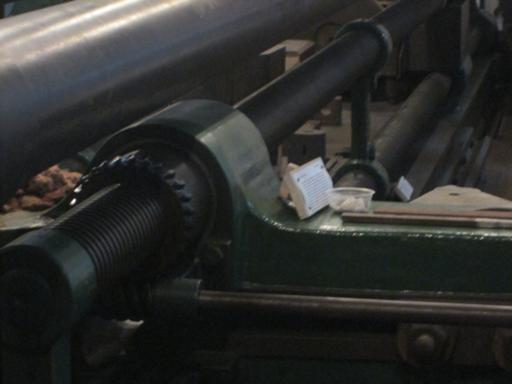

Looking towards the cylinder.

Non-cylinder end.

Secondary arm.

Arm pivot, magnifying lever action.

Weighted arm and measuring scale.

A sample of iron, secured in place.

And after breakage.

Here's one we broke earlier.

The crew of volunteers.

More details.

An ancient (well, probably early 1900s) calculating machine.

Tension tester used at the Irving Parachute Factory in Letchworth to

check risers. Used here on a packing strap

which disintegrates satisfactorily

and not only can you read off the poundage (in better light)

but a series of eight ratchets gives 2-ounce resolution within the

grad marks.

Another tension tester, used at Irving for broader straps.

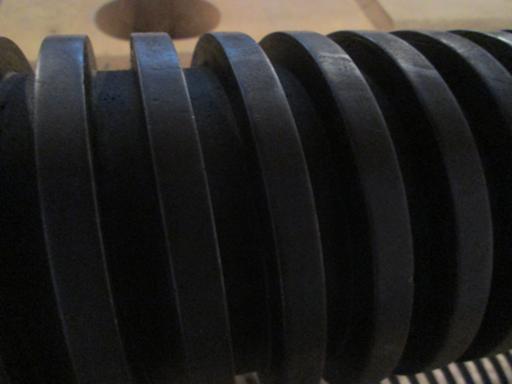

Torsion tester, cranked by turning the worm gear; apparently it's all

too easy to apply quite excessive force.

One of the mains from the London Hydraulic Power Company, on which the

works ran for much of its life.

More tension testers.

Tension tester for concrete. Lead shot runs out of the tower on

the right into a bucket, to put load on the "dog-biscuit" sample; when

the sample breaks, the bucket hits a lever at the bottom and stops the

flow of shot. It can then be weighed.

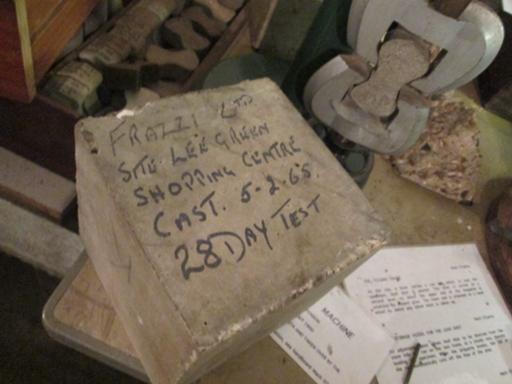

Sample block - we happened to visit on its birthday. I used to live

near there, and

this

is what it looks like today; it's possible that the bottom level still

consists of the original blocks. (The current owners want to knock it

down and replace it with an Asda, even though there's a perfectly good

Sainsbury's across the road and there's local demand for small shops

as well as supermarkets. The current owners are St Modwen Properties,

and that's what they want to do with everything they buy.)

The hydraulic press used to test those cubes (piston fully extended,

cylinder at the base).

Underside of the Machine above.

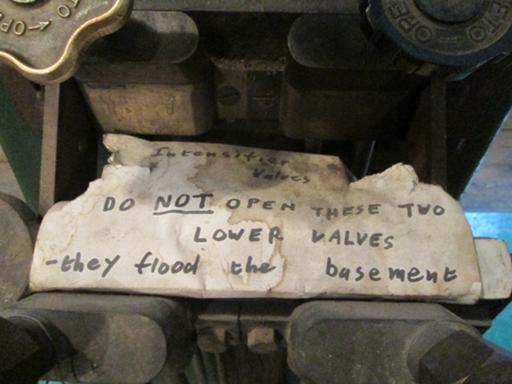

Hydraulic intensifier, used to bring the 750ish psi of the LHP Company

up to the 4,500 or so needed for the Machine.

Impact testing machines (1916 or so).

1920s chain tester.

Counterweight for the Machine.

It's all a bit basic, and desperately reliant on volunteers, but one

can get up close to the machinery and get a good sense of the scale of

19th- and 20th-century industrial hardware. Highly recommended, though

it isn't often open; check the

museum web site.

Comments on this post are now closed. If you have particular grounds for adding a late comment, comment on a more recent post quoting the URL of this one.